VISI-FLO® 1500 Series Sight Flow Indicators

Designed for applications with maximum operating pressure of 400 psig (27.6 bar) and/or temperature of 350ºF (177ºC). Special high-temperature seals are also available; consult factory for details. Flanged sight flow indicators have been engineered to meet the demands of a variety of industrial processes, including chemical and petrochemical applications.

- Exclusive 3-Year “No-Leak” Guarantee: An innovative radial seal creates a constant and uninterrupted sealing force between the body and outside diameter of the glass lens for a longer-lasting and better seal than conventional flat seals

- Maintenance-Free Design: Bolt-on-body design requires no special maintenance or torqueing sequence in order to prevent leaks, resulting in safer operation than units using tie rods to fasten the lens and seal to the body

- Dimensional Interchangeability: Feature end-to-end dimensions that match Jacoby-Tarbox and Penberthy and other manufacturers' units. Available in 3/4", 2", 3" and 4" sizes

- High Vacuum-Service Rating: ?Rated for vacuum service up to 635 mm (25”) at 85.5% vacuum, which equates to 12.3-psi (0.84 bar) vacuum

- Four Indicator Styles: Drip Tube, Propeller, Bi-Directional Flapper, Bi-Directional Plane

- 3-Day Shipping for Most Items

Four Indicator Styles

|

|

| Drip Tube – Ideal for gravity,

extremely low or intermittent flow.

Keeps product from dripping on the

glass. Assures constant see-through

for vertical lines. |

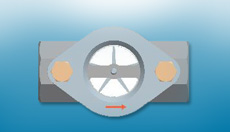

Propeller – The best way to show

flow of opaque liquids. Ideal for

observation at a distance. Flow from

right to left is standard. Specify if left

to right flow is needed.

Not recommended for flow rates

above 100 GPM. |

|

|

| Bi-Directional Flapper –

This indicator points in either

direction to show you at a glance

which way the liquid is flowing. |

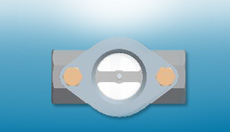

Bi-Directional Plain – When the

color and clarity of your liquid are of

prime importance. |