KPS, is proud to announce its new 3” (110/90 mm) double wall HDPE piping system. Designed to meet customer demand, the new 3” system is engineered for medium to high flow applications on forecourts, data centres and backup and primary generators including fill lines and other fuel and vapour lines where the highest standards are required.

“Our new 3” system expands the KPS portfolio even further, offering customers a range of double wall piping to suit any application, including 1”, 2”, 4”, and 6”. Carefully designed by the KPS technical engineering team in Kungsör, Sweden (the home and birthplace of KPS), the 3” system has the same easy-install conductive properties KPS piping is known for.”

– Staffan Helleday, KPS Product Manager

EN 14125 Approved

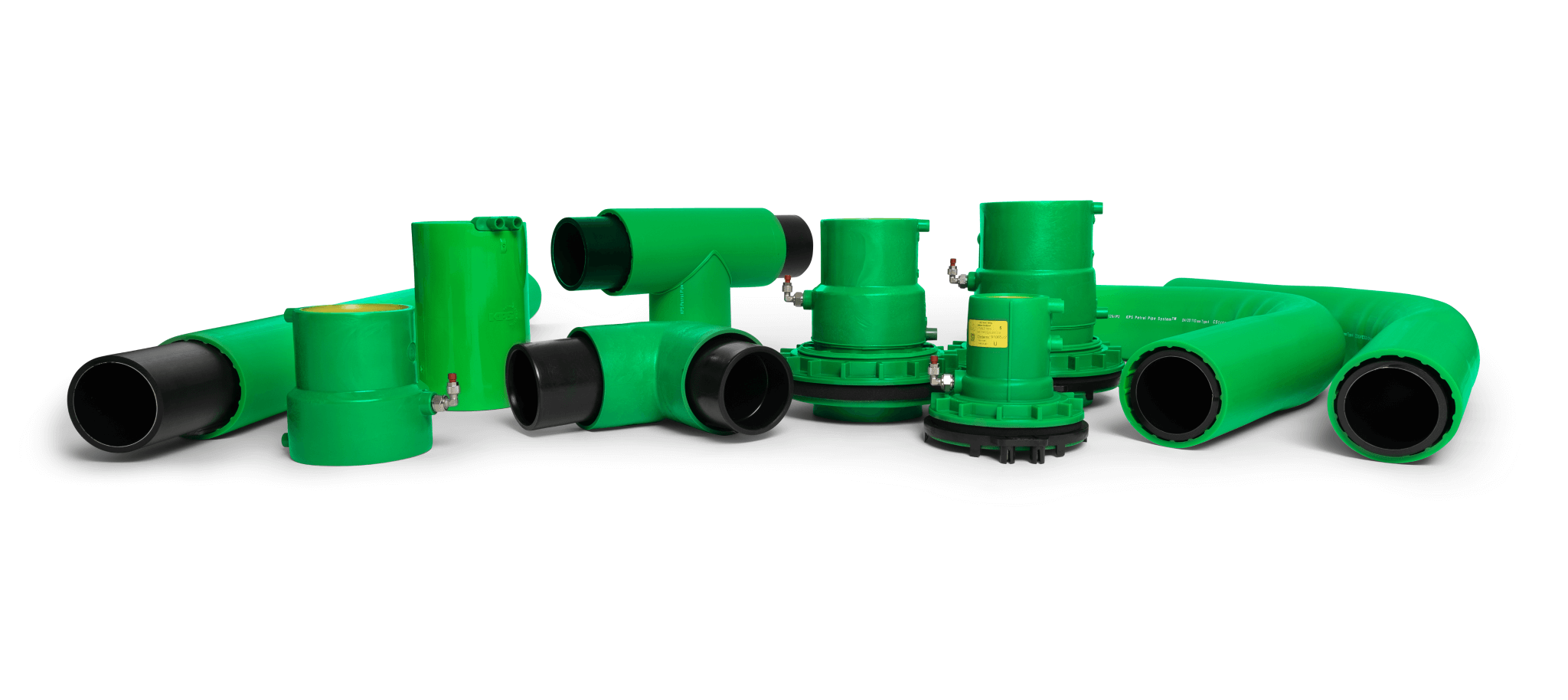

Certified to EN 14125, the KPS 3” system consists of a 90 mm primary containment pipe and a 110 mm secondary containment pipe, providing an extra layer of protection and enabling interstitial monitoring. The zero-permeation design includes an EVOH layer and is designed for sensitive liquids like fuels and chemicals, including petrol, diesel, biodiesel, ethanol blends, AdBlue, Jet-A1, alcohols, acids and other chemical products.

Engineered for Easy Installation

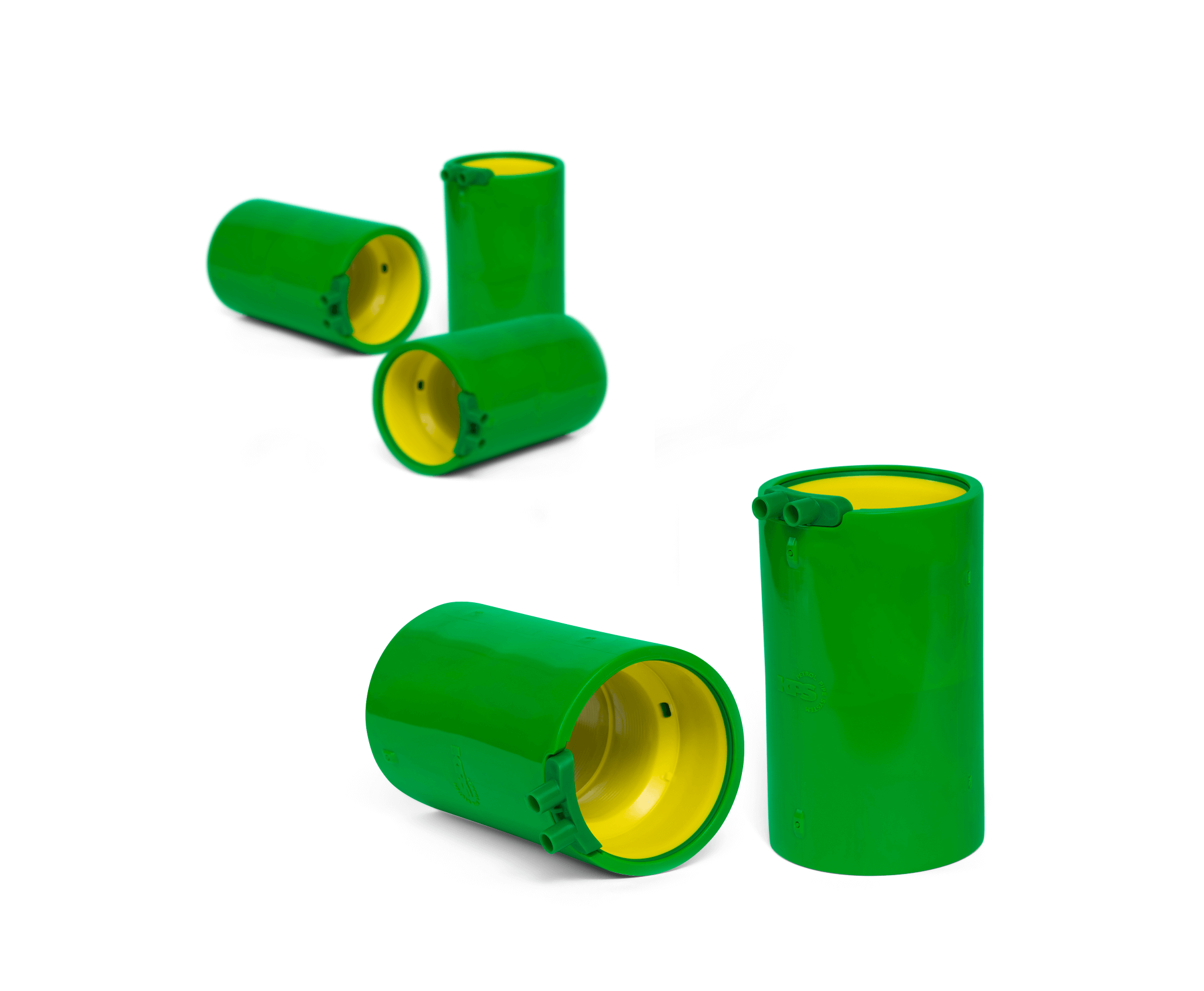

Like all KPS piping, the new 3” system is engineered for installers to reduce cost and build time. The complete range of fittings and components are electrofusion welded, with no butt welds needed, and supported by the KPS technical team, including training and certification (classroom and on-site).

Explore the full system here.

KPS’ installer friendly 3” double wall fittings weld both pipe walls simultaneously

Featured In

MobilityPlaza

erpecnews